ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

2024-05-13 3897

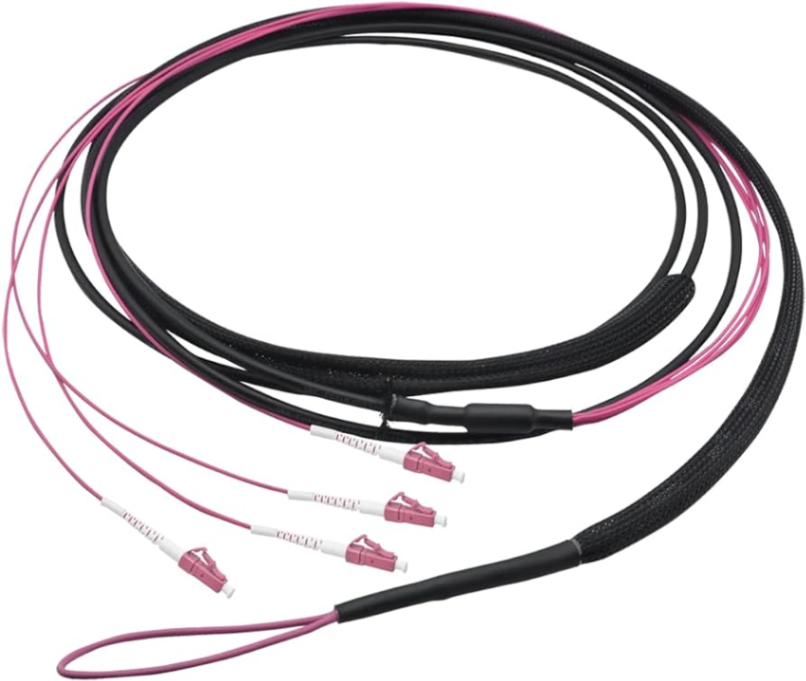

Title: The Dilemma: Premade or Custom Fiber Optic Cables? Navigating the Best Fit for Your Needsᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

When it comes to choosing between premade and custom ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.s, the decision often hinges on a variety of factors unique to your needs and applications. Both options offer distinct advantages and disadvantages, and a thorough understanding of their differences can help you navigate towards the best fit. Here's a ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. in-depth look at the key considerations:

Premade Fiber Optic Cables:

Advantages:

Cost-Effectiveness: Premade cables offer a cost-efficient solution due to their mass production. This makes them a budget-friendly choice for many applications.

Quick Deployment: Standardized premade cables are readily available, enabling fast shipping and installation, often with minimal lead time.

Industry Compliance: These cables adhere to industry standards, ensuring compatibility and performance across various systems and networks.

Disadvantages:

Limited Customization: Premade cables come in standard lengths, connector types, and specifications, limiting their ability to meet unique requirements.

Lack of Flexibility: For specialized or niche applications, a standard premade cable may not be the ideal solution.

Custom Fiber Optic Cables:

Advantages:

Tailored Solutions: Custom cables can be designed and manufactured to meet specific requirements, including unique lengths, connector types, fiber counts, and other specifications.

Ideal for Unique Applications: Whether it's a challenging installation environment or specialized network architecture, custom cables can be tailored to fit the job perfectly.

Long-Term Value: While initial costs may be higher, custom cables often provide better value over the long term by meeting exact needs and reducing waste.

Disadvantages:

Higher Initial Investment: Custom cables require additional time and resources for design, manufacturing, and testing, resulting in higher upfront costs.

Longer Lead Times: The design and manufacturing process for custom cables takes time, resulting in longer lead times compared to premade cables.

Navigating the Choice:

Define Your Needs: Start by clearly outlining your specific requirements and applications. This will help you determine if a premade or custom cable is the best fit.

Consider Cost and Timeline: Weigh the initial costs and delivery times of both options against your budget and timeline constraints.

Consult with Experts: Discuss your needs with a ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. manufacturer or distributor. They can provide expert guidance on the best option for your application and help you understand the trade-offs between premade and custom cables.

Ultimately, the choice between premade and custom ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.s depends on your unique requirements and applications. By carefully considering factors like cost, timeline, flexibility, and customization options, you can make an informed decision that will meet your needs effectively.