ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

How to Detect, Prevent, and Repair Fiber Optic Cable Damage

ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.

Fiber optic cable damage can disrupt critical communication networks, slow down data transfer, and lead to costly downtime. Whether you’re managing a telecom infrastructure, a data center, or a home network, understanding the causes, signs, and solutions for ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. damage is essential. This guide provides actionable steps to safeguard your cables and maintain peak performance.

Common Causes of Fiber Optic Cable Damage

Physical Stress:

Excessive bending (violating the bend radius), crushing, or kinking during installation.

Rodent bites or accidental cuts during construction.

Environmental Factors:

Moisture ingress due to damaged outer jackets.

Temperature extremes causing expansion/contraction.

Human Error:

Improper handling, such as pulling cables too tightly.

Poor splicing or connector installation.

Signs of Fiber Optic Cable Damage

Intermittent or Complete Signal Loss: Sudden drops in network performance.

High Attenuation: Weak signal strength measured by an OTDR (Optical Time-Domain Reflectometer).

Visible Defects: Frayed jackets, cracked connectors, or exposed fibers.

How to Diagnose Fiber Optic Cable Damage

Visual Inspection:

Use a fiber microscope to check connectors for dirt, scratches, or misalignment.

OTDR Testing:

Deploy an OTDR to pinpoint the exact location of breaks or bends.

Power Meter Testing:

Measure light loss between the transmitter and receiver.

5 Ways to Prevent Fiber Optic Cable Damage

Respect the Bend Radius:

Never bend cables tighter than 10–20x their diameter (e.g., 30mm bend radius for a 3mm cable).

Use Protective Conduits:

Shield outdoor cables with arᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.d tubing to resist environmental hazards.

Avoid Tension:

Install cables with slack loops to prevent stretching.

Regular Maintenance:

Clean connectors with lint-free wipes and isopropyl alcohol to prevent debris buildup.

Label and Document:

Mark cable routes to avoid accidental cuts during renovations.

Repairing Fiber Optic Cable Damage: Step-by-Step

Locate the Damage:

Use an OTDR or visual fault locator (VFL) to identify the issue.

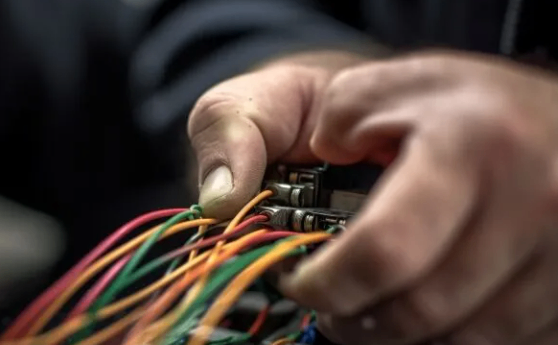

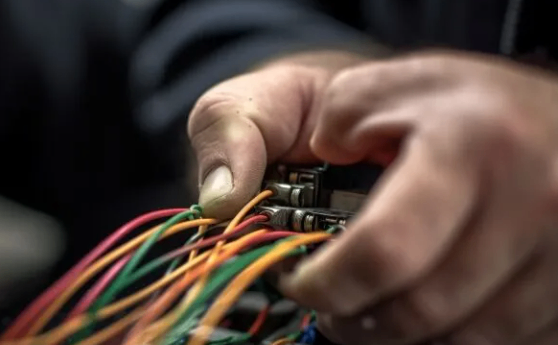

Prepare the Cable:

Strip the damaged section and cleave the fiber ends.

Splice or Replace:

For minor breaks: Perform fusion splicing to reconnect fibers.

For severe damage: Replace the entire cable segment.

Test and Secure:

Validate repairs with a power meter and seal splices in protective sleeves.

When to Replace vs. Repair Fiber Optic Cable Damage

Repair: Small bends, minor jacket tears, or dirty connectors.

Replace: Extensive physical breaks, waterlogged cables, or repeated signal failures.

Industries Most Affected by Fiber Optic Cable Damage

Telecommunications: Network outages impact customer connectivity.

Healthcare: Interrupted data transmission delays critical patient diagnostics.

Smart Manufacturing: Broken cables halt automated production lines.

Conclusion

Proactively addressing ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. damage minimizes downtime and extends network lifespan. By combining preventive measures with swift repairs, businesses can ensure uninterrupted high-speed data flow. For complex installations, always consult certified technicians to adhere to industry standards like ANSI/TIA-568.

FAQ

Q: Can ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. damage cause a fire hazard?

A: No—fiber optics transmit light, not electricity, so they pose no fire risk.

Q: How long do ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u.s last before damage occurs?

A: With proper care, they can last 20–30 years, but environmental factors may shorten this.

Q: Is it safe to repair ᐃᑭᒋᐊᕐᕕᖓ ᑲᑉᐳᑎᓗᒍ %u. damage myself?

A: Basic cleaning or connector replacement is DIY-friendly, but splicing requires specialized tools and training.